|

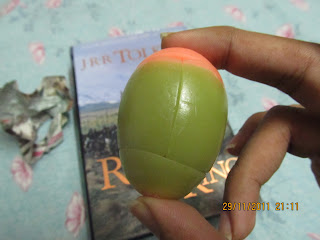

| Egg as a whole |

|

| Egg being disassembled |

|

| Egg is broken into 4 parts |

|

| front view |

|

| Central portion top view. Observe the grains alignment , outward |

One year back when i was in second year and was being taught by the legendary Satyendra sir i was highly inspired by his lectures on metal casting. He is an extraordinary teacher and his lectures were very knowledgeable. He taught us Manufacturing Technology 1 . Imagine me, a pyromaniac by birth being taught about metal casting. In tenth i went to Vizag steel plant and there i saw a river of molten metal flowing a few feet away from me. Then i realized that there is nothing which can match the beauty of molten metal.

So my passion for metal casting went to such heights that one day i decided to really do it ! Since its not easy to melt metal i thought of doing it on wax.

With wax :

I took an egg, made a small hole on the top of it and emptied all the contents. Then after it dried i used a funnel and filled the egg shell with molten wax. After a few minutes the wax would solidify and contract. Since i dint use a riser i had to manually fill the void every time. One day i managed to break open a wax casting an inside i found shrinkage voids.

1) The two depressions you see in the central green portions are the shrinkage voids, I had no intention to create them but they are the result of multi-directonal cooling.

2) You can see the direction of cooling by following the way the grains are aligned(radially outward). It is multi directional cooling.

|

| Observe the depressions in the central green portions, shrinkage voids |

With metal :

I went to my dads yard and took some basic training with the oxy acytlene torch. I made a small hole in the ground and cut a sprue for the metal to enter. I placed a lump of pig iron by the mouth of the hole and lit the torch. The lump got very hot and melted then it drained into the hole i made in the ground. The metal was soo hot that it was glowing white. After the hole filled i waited for a while and later cooled it by pouring water. Then i plucked it out of the hole and this is what i have achieved ......an ugly lump of metal oxide .

|

| Porous lump , mostly metal oxide |

Im still trying to do better. My aim is to make a metallic egg.

No comments:

Post a Comment